Torque control can have a positive impact on the energy consumption of a thickener.

By monitoring the torque on the drive system and adjusting the speed of the rake or scraper accordingly, torque control can help to ensure that the thickener is operating at the optimal speed for the specific application.

When the thickener is operating at the optimal speed, it can reduce the amount of energy required to move the rake or scraper and increase the efficiency of the thickening process. This can help to reduce the overall energy consumption of the thickener and decrease operating costs.

Additionally, torque control can help to prevent excessive torque on the drive system, which can reduce the risk of equipment damage and the need for repairs or replacement. This can further reduce energy consumption and operating costs by minimizing downtime and maintenance requirements.

Torque control can help to optimize the operation of the thickener, reduce energy consumption, and improve the efficiency and reliability of the equipment.

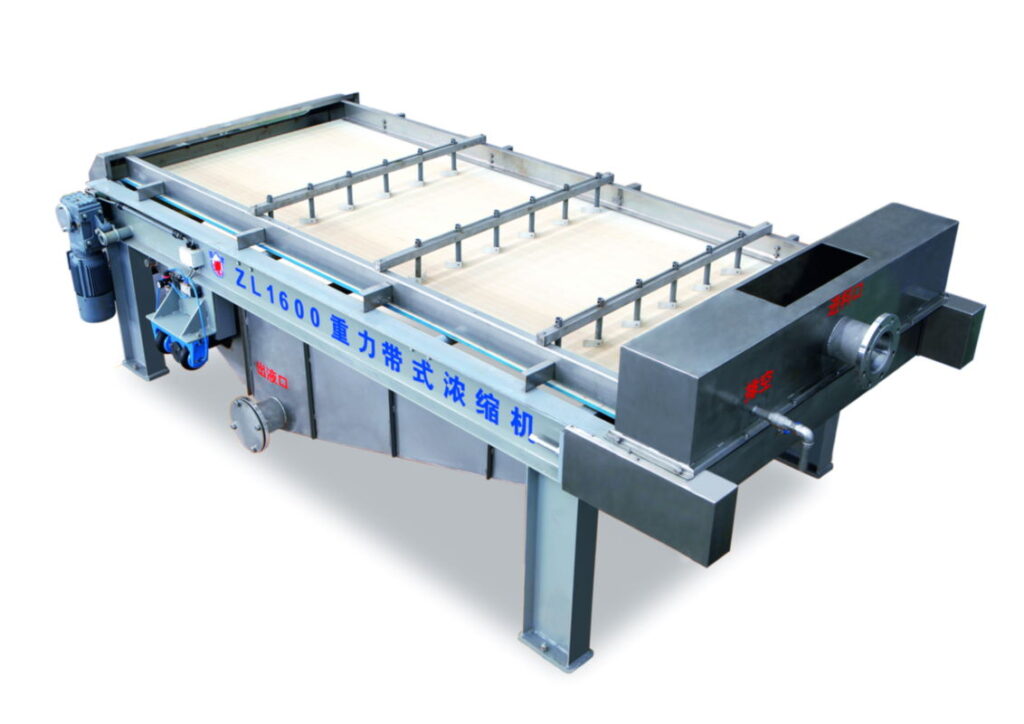

Thickner manufacturer produce thickeners can be operated in different configurations, including batch or continuous operation, and can use different types of rakes or scrapers, depending on the specific application. Some thickeners also incorporate additional features, such as automatic rake lifting and torque control, to improve the thickening process and increase efficiency.

Thickeners are commonly used in the mining industry to separate solids from liquids and recover valuable minerals from ores. They are also used in the chemical and wastewater treatment industries to increase the concentration of solids in a liquid before further processing or disposal.